As drivers of large vehicles become more aware of traffic safety, wireless reversing cameras have become an indispensable safety equipment for large vehicles. Compared with traditional wired cameras, wireless cameras are much easier to install, eliminating the need for tedious hole drilling and complicated wire connections.

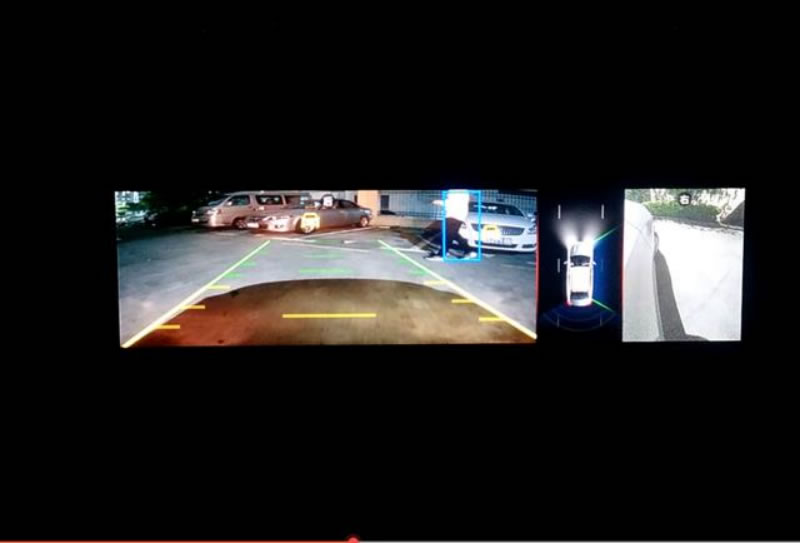

Typically, wireless reversing cameras are mounted at the rear of large vehicles, usually on the rear roof. This location allows the camera to have a better viewing angle, giving the driver a wide view of the blind spot behind the vehicle. When it is necessary to reverse the vehicle, the reversing guideline provided by the camera intelligently indicates where the vehicle will be parked, avoiding the need for the driver to frequently check different mirrors and making the reversing man oeuvre much easier.

When it comes to the power source of the wireless reversing camera, the abundant power resources of the large vehicle itself can be utilized. Various systems inside the vehicle, including lights, air conditioning and displays, are powered through the on-board power supply. The camera, being a part of it, also requires power to ensure its proper functioning and wireless transmission of video signals to the monitor. Depending on the characteristics of a large vehicle, different power supply options are available, and connecting a taillight power supply is one of them. Reversing taillights are a common power supply method, as they are matched to the gear switch to ensure that the camera is switched on when needed, meaning that when the vehicle is in reverse gear, the camera power is activated, and the monitor screen automatically switches to the rear view.

Overall, mounting a wireless reversing camera near the taillights of a large vehicle is a good option as it ensures that the camera’s power supply is closest to the taillights, making it more convenient. If you wish to install the power supply inside the cabin, you may need the help of a professional technician. These modern cameras play a vital role in improving the safety and convenience of driving large vehicles. The constant upgrading of wireless cameras has also led to smarter features that offer more possibilities for the driving experience.